To stay on track for global net zero emissions by 2050 under the Paris Agreement, annual investments must reach an average of $5.6 trillion from 2025 onward, current levels miss this mark by 37 per cent. BV has so far committed $60 million to companies driving the energy transition, emissions reduction, and the circular economy.

Breakthrough Victoria is paving the way for innovators to commercialise their ideas across our growth sectors to help lead innovation and tackle complex challenges confronting society. By supporting and investing in the sectors of ‘Clean Economy’ and 'AgriFood', we're contributing to climate solutions and supporting the world’s energy transition that will require an estimated $35 trillion USD by 2030.

Below are some of these companies, and how their impact will contribute to achieving global clean economy goals.

ELECTRALITH

Electralith is a Victorian company that is rapidly developing the cleanest, most versatile and most cost-effective process to extract and refine lithium, a fundamental element of a sustainable future.

THE PROBLEM

The global lithium market is expected to grow from $26 billion in 2025 to $37 billion by 2027. However, supply is limited by traditional mining methods like evaporation ponds and hard rock mining, which are inefficient, water-intensive, and environmentally harmful. For instance, producing one ton of lithium via evaporation ponds can take over 18 months and 2.2 million litres of water. Hard rock mining also generates carbon emissions and chemical waste.

Direct Lithium Extraction (DLE) offers a faster, more efficient, and eco-friendlier alternative, as highlighted by Goldman Sachs (April 27, 2023). Still, DLE requires water, chemicals, and a carbon-intensive refining process, often completed in countries like China, adding supply chain complexity.

THE SOLUTION

ElectraLith’s DLE-R process addresses these issues by offering a breakthrough one-step solution for lithium extraction and refining from any brine source using proprietary membrane technology initially developed at Monash University. Unlike other DLE methods, DLE-R requires no water or harmful chemicals and is fully scalable, using modular, off-the-shelf equipment. Additionally, the technology has the potential to be powered entirely by renewable energy, providing a significant cost advantage to lithium miners.

ElectraLith

RAYGEN

RayGen was founded in 2010 by John Lasich. At that time, the company consisted of three people and one big idea: to develop the world’s lowest-cost, highest-efficiency solar technology. By focusing sunlight onto a small area, RayGen’s approach to solar captures almost all of the sun’s energy as electricity (via high-efficiency solar cells) and heat (via water used to actively cool the solar cells).

By 2019, the market needed bulk storage that could soak up low-value, excess renewable energy. Work began on integrating RayGen’s photovoltaic technology with an electro-thermal energy storage solution that would cater to customers day and night.

THE PROBLEM

Energy storage is key to supporting the energy transition and growing renewable generation. The IEA projects storage capacity must increase over 100x by 2050. Victoria aims for 95% renewable power and at least 6.3GW of storage by 2035.

THE SOLUTION

RayGen’s innovative solar PV and thermal water-based storage technology supports the shift to renewables by offering 70% round-trip efficiency, outperforming other electro-thermal systems. Its proprietary solar modules generate nearly 2,000 times more power under concentrated sunlight, and combined with thermal water storage, deliver a world-leading, low-cost, long-duration energy solution.

RayGen

NUMBER 8 BIO

Number 8 Bio, a leading innovator in sustainable agriculture technologies, based in Sydney.

They have developed a groundbreaking technology known as "Performance Digestion". This revolutionary approach utilises advanced metabolic engineering, synthetic biology, and chemistry to create feed supplements that address two critical challenges in livestock farming: reducing methane emissions and enhancing animal productivity.

THE PROBLEM

Growing demand for meat and dairy is increasing livestock numbers, but ruminant methane emissions already contribute up to 15% of global greenhouse gases. Since methane traps 80 times more heat than CO₂ over 20 years, cutting it is key to slowing climate change and improving livestock efficiency.

THE SOLUTION

Number 8 Bio’s "Performance Digestion" technology powers their BetterFeed products, combining metabolic engineering and synthetic biology to reduce methane emissions by up to 90% with just 25g of additive daily. It also boosts animal productivity by redirecting energy toward growth, enhancing meat, milk, and wool production.

Number 8 bio® | Reducing enteric methane with BetterFeed™

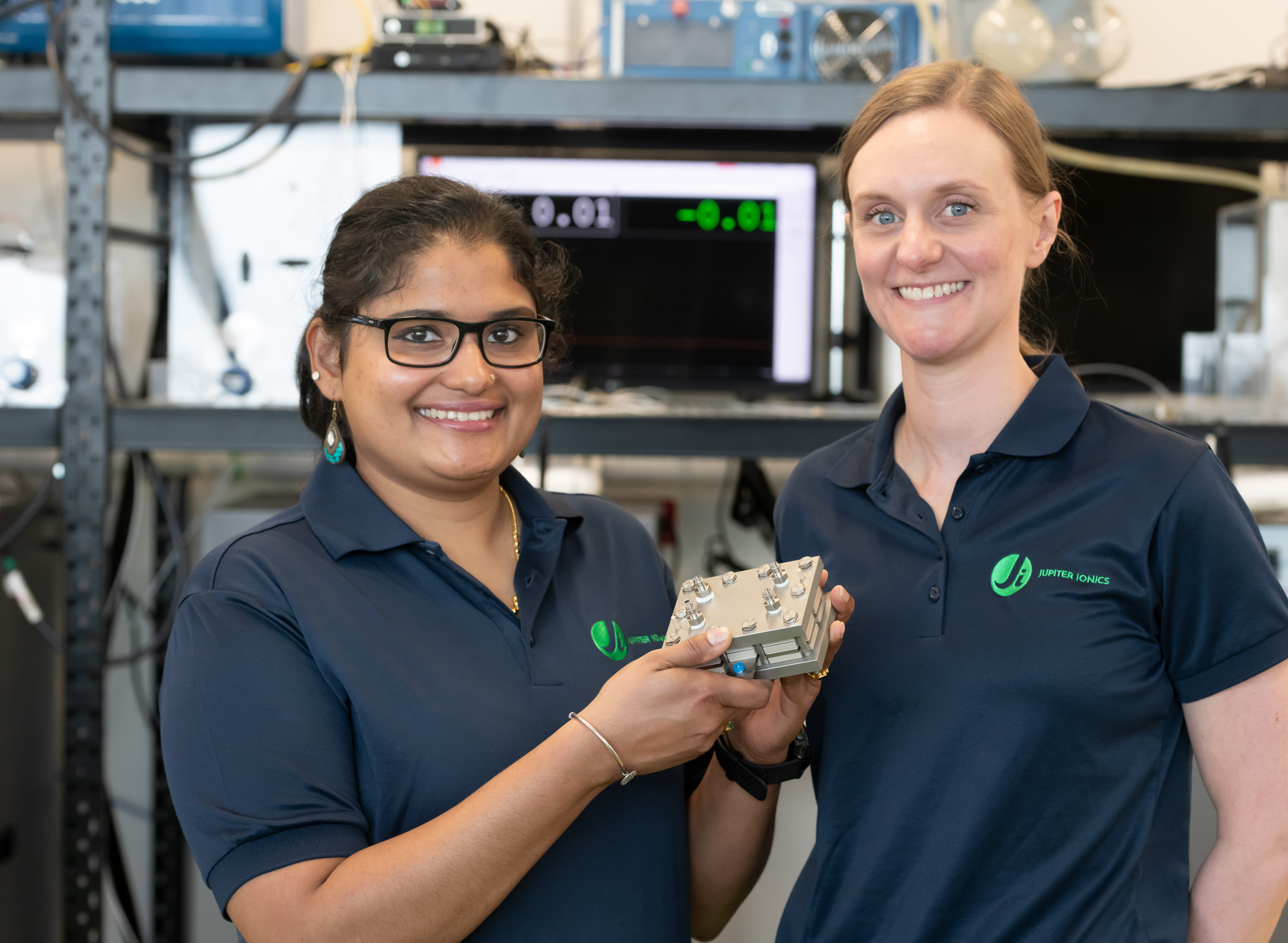

JUPITER IONICS

Jupiter Ionics is a Victorian company that has developed a unique, patented, and innovative electrolytic cell technology to produce green ammonia.

THE PROBLEM

Traditional ammonia production relies on fossil fuels, driving high carbon emissions and creating price volatility in fertiliser supply, which impacts farmers and regional communities.

THE SOLUTION

Jupiter Ionics has developed a patented electrolytic cell technology that produces carbon-neutral green ammonia using renewable electricity, water, and air. Their modular, scalable system offers a stable, sustainable, and cost-effective fertiliser source for the agricultural sector.

BYGEN

Bygen are a Victorian company turning agricultural waste into activated carbon - a toxin filtering material – via a low-cost process with a better carbon footprint than conventional carbon activation production methods.

THE PROBLEM

Traditional activated carbon production is greenhouse gas intensive, costly, and consumes large amounts of water. Agricultural waste often goes unused, and current technologies struggle to efficiently remove persistent environmental toxins like PFAS.

THE SOLUTION

Bygen has developed a patented, low-cost process that uses agricultural waste to produce activated carbon with a significantly lower carbon footprint. Their technology reduces CO₂ emissions, cuts water use, and repurposes agricultural byproducts, while delivering better PFAS removal compared to conventional methods.

Bygen: Activated Carbon Producer and Supplier in Australia

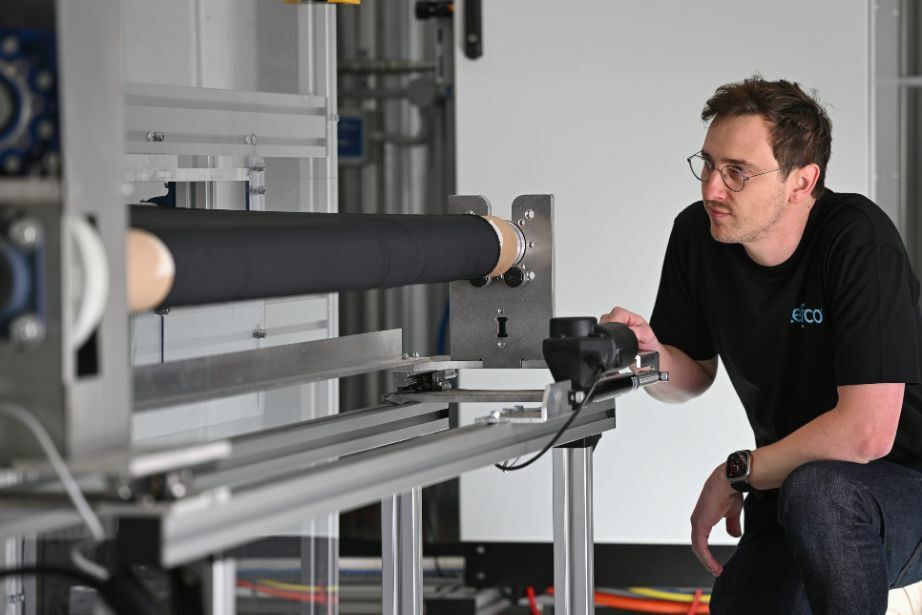

XEFCO

Xefco was founded by Brian Conolly and Tom Hussey back in 2018. They developed Ausora™ , a proprietary water-free dyeing and finishing technology, allowing for dyeing and finishing of textiles to be completed without the use of water.

THE PROBLEM

The US$2 trillion textile market produces about 600 billion metres of fabric annually. However, it is also considered one of the most polluting industries in the world, responsible for 20% of global water pollution and 3% of global carbon emissions.

An eco-conscious preference for more sustainable fashion has been growing among consumers in recent years. Consumers have become increasingly aware of the negative environmental impact of the current textiles production system, including the harm caused by toxic chemicals in the dyeing the finishing process.

THE SOLUTION

Xefco’s Ausora™ technology can deliver significant environmental outcomes more efficiently than traditional methods. The unique capabilities of Ausora’s plasma enhanced chemical vapour deposition (PECVD) coating technology significantly reduces the complexity of the chemistry involved and opens up avenues for the use of biobased and sustainably sourced chemicals.

Since the technology doesn’t require any water, it enables the dyeing and finishing process to be located closer to production, and at a major cost benefit to the dyeing mill and garment manufacturer because of the lower inputs required.

It also requires 86 per cent less energy compared to traditional fabric dyeing and finishing methods, potentially reducing global carbon emissions.

As a result, Xefco’s solution eliminates toxic dyeing and finishing chemistry from the textile supply chains, reducing exposure of toxic materials to their workers and their communities.

The textile dyeing and functional finishing markets are significant opportunities for Xefco, with major brands looking for alternatives that are both environmentally friendly and more aligned with customer expectations.

EDEN BREW

Eden Brew is an Australian company using science to emulate the proteins in cow’s milk to produce animal-free dairy products.

THE PROBLEM

Dairy products are considered a food staple in households globally; however, cow and alternative milks come with an environmental cost in water and land use. The Food and Agriculture Organisation of the United Nations estimates a need to produce 70 per cent more food by 2050 to meet the demand for high-quality protein.

Traditional food manufacturing and supply methods are forecast to struggle to meet this global demand.

THE SOLUTION

Eden Brew will scale fermentation-based manufacturing and utilize existing milk and dairy production techniques and infrastructure.

This approach aims to increase the supply of nutritious food sustainably with a process that uses 100x less water than traditional cow’s milk production.

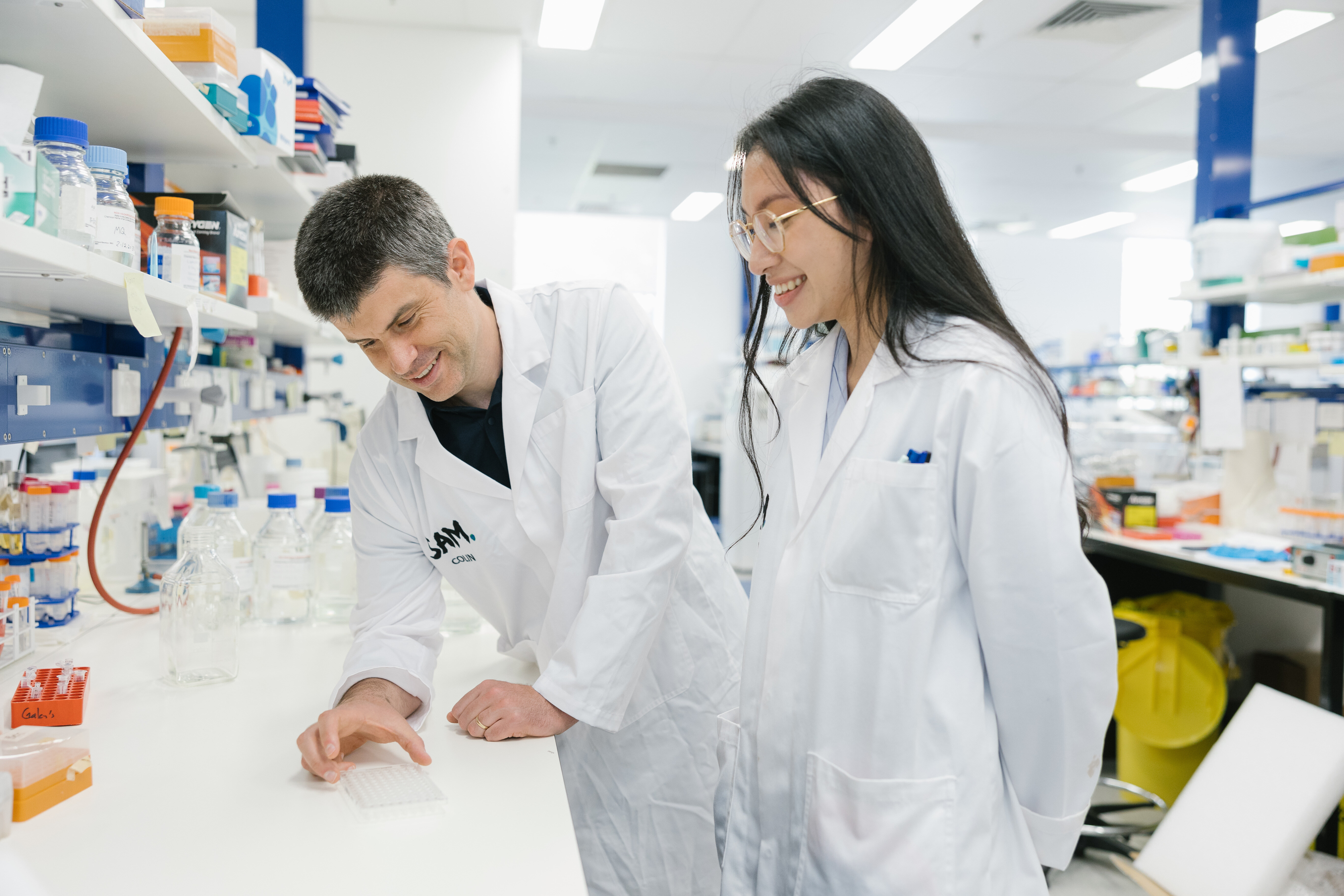

SAMSARA ECO

Samsara Eco was born out of the Australian National University (ANU) in 2021 as researchers looked for solutions to tackle plastic pollution and failures in existing recycling technology.

THE PROBLEM

Plastic pollution is a significant environmental issue, with single-use plastics making up around one-third of Victoria’s litter. Existing recycling technologies often fail to effectively recycle plastics, leading to a growing accumulation of plastic waste. This not only harms ecosystems but also contributes to the climate crisis by increasing the demand for new plastic production from fossil fuels.

THE SOLUTION

Samsara Eco has developed innovative plastic-eating super enzymes that break down plastic into its core molecules, regardless of color and shape. These molecules can then be reused by manufacturers to create new plastic items. This process allows for the infinite recycling of plastic, eliminating the need to produce new plastic from fossil fuels. The company’s long-term goal is to process 1.5 million tonnes of plastic per year by 2030.

Samsara Eco - Infinite Recycling to End Plastic Pollution

KITE MAGNETICS

Developed at Monash University, Kite’s Aeroperm® technology is designed to seamlessly integrate into existing manufacturing processes, providing an immediate boost in efficiency and vehicle-wide cost savings.

The advanced magnetic materials reduce stator core energy losses by up to 97 per cent, allowing for smaller, lighter and more efficient electric motors that improve overall vehicle performance.

THE PROBLEM

Electric motors face challenges related to efficiency, range, and cost. Traditional electric motor materials, such as iron silicon steels, have significant energy losses, which limit the performance. These inefficiencies also lead to higher costs and increased weight, making it difficult to maximize the potential of electric motors.

THE SOLUTION

Kite Magnetics addresses these issues by developing advanced nanocrystalline magnetic materials, specifically their Aeroperm® technology. This technology significantly reduces stator core energy losses by up to 97%, allowing for smaller, lighter, and more efficient electric motors.

By integrating Aeroperm® into existing manufacturing processes, Kite Magnetics aims to enhance the overall performance and cost-effectiveness of electric vehicles, contributing to the broader adoption of sustainable transportation solutions.

Nanocrystalline stator cores | Motor efficiency | Kite Magnetics